Boost Your Packaging Refine With a Dependable stretch wrapping machine for Ideal Efficiency

In the complex world of logistics, an efficient packaging procedure is a vital element that can considerably influence a firm's bottom line. The consolidation of a reliable stretch wrapping machine not just enhances efficiency however also makes certain the stability of goods throughout transit - stretch wrapping machine.

Recognizing the Function of a stretch wrapping machine in Product Packaging

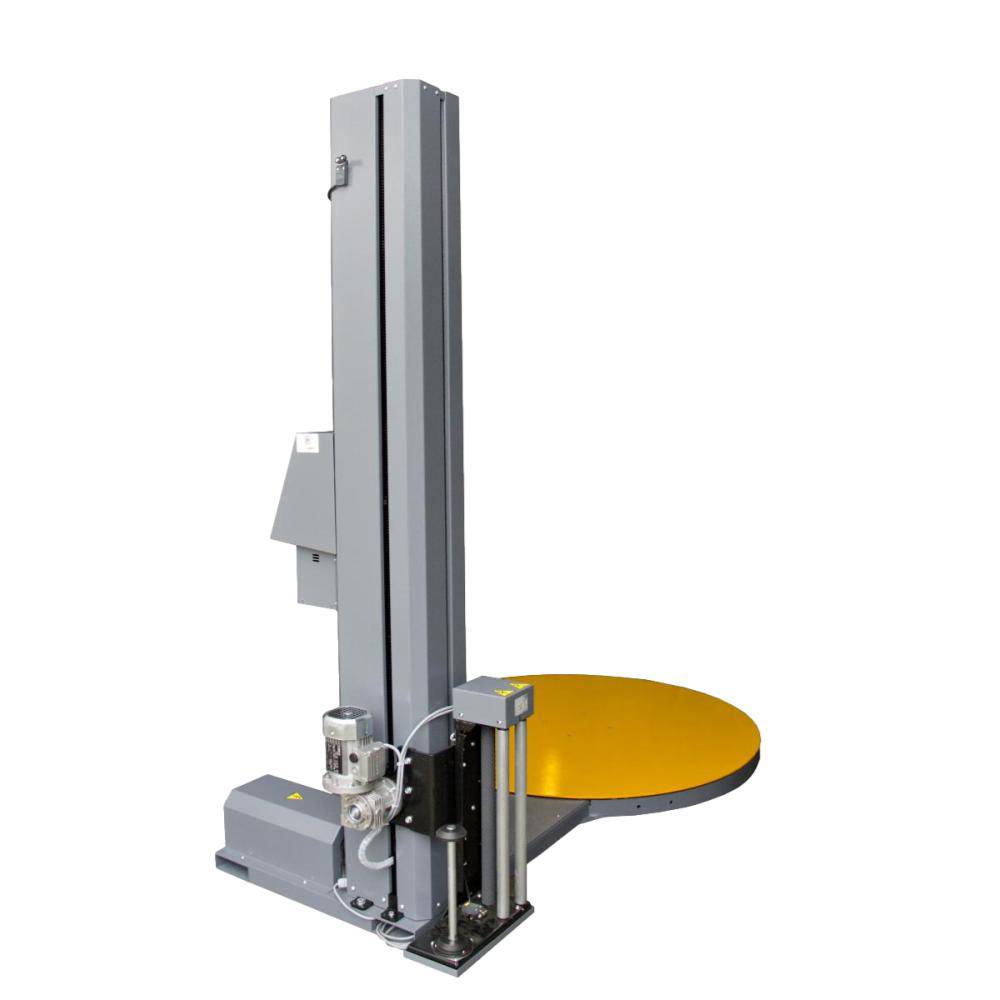

Making sure product security during transit, a stretch wrapping machine stands as a pivotal possession in the packaging market. Its primary function focuses on encapsulating things in a protective layer of movie, thus maintaining product honesty and reducing damages risks during transport.

The device's procedure is elaborate yet reliable. Item are positioned on a revolving base while the film is untangled from a fixed roll. As the turntable spins, the movie is used uniformly over the items, ensuring total insurance coverage.

This machine's importance expands beyond mere covering. stretch wrapping machine. It boosts the piling stability of products, lowering the likelihood of mishaps. Additionally, it safeguards items from dust, wetness, and various other ecological factors, maintaining their high quality until they reach the customer

Essentially, a stretch wrapping machine is a vital device for companies looking for to optimize their product packaging procedure, safeguard their items, and streamline their logistics operations. Its role is essential to the reliable and reliable performance of the modern-day product packaging sector.

Trick Attributes to Consider When Picking a stretch wrapping machine

When picking a stretch wrapping machine for product packaging objectives, numerous vital attributes require factor to consider. These include examining the maker's effectiveness, comprehending its load capacity, and analyzing its resilience and upkeep demands. A notified decision depend upon an extensive analysis of these variables.

Although performance might not be the first point you consider when thinking about stretch wrapping machines, it is an essential variable that can dramatically affect your packaging process. A reliable maker can substantially lower waste, lower prices, and enhance productivity. When reviewing effectiveness, consider the equipment's speed. A faster maker can wrap a lot more packages in much less time, increasing your procedure's outcome. Also, look for programmable setups, which can personalize the wrapping procedure to suit various items, minimizing unneeded use of products. Additionally, an effective machine must require very little upkeep, guaranteeing continual operation without regular disturbances. The machine's energy intake is another critical aspect, as a machine that uses much less power can cut operating expenses. Bear in mind, an effective equipment guarantees ideal performance.

The Effect of a Dependable stretch wrapping machine on Efficiency Levels

Buying a trustworthy stretch wrapping machine can dramatically improve efficiency levels in a packaging procedure. These makers automate the wrapping process, permitting effective and constant performance that outmatches hand-operated covering techniques.

A trustworthy device reduces downtime caused by mechanical failings or maintenance requirements. High-quality stretch covering machines likewise have flexible setups for different item kinds.

Furthermore, these equipments require less human intervention, liberating staff members to concentrate on various other essential tasks. This optimization of human resources can cause a rise in general functional performance.

Essentially, a trustworthy stretch wrapping machine is a valuable investment that can boost click here to read productivity levels in a packaging procedure, providing considerable advantages in efficiency, adaptability, and resource exercise.

Ways in Which a stretch wrapping machine Lowers Waste

A stretch wrapping machine's function in waste decrease is multifaceted and considerable (stretch wrapping machine). Not only does it decrease material usage by effectively wrapping items, yet it additionally safeguards items from damage throughout handling and transportation. This double advantage cause notable cost savings and advertises sustainability in the product packaging procedure

Minimizing Product Use

Expense and Time Cost Savings: The Financial Advantages of a stretch wrapping machine

In addition, the maker's consistent covering technique decreases product damages, decreasing replacement prices and enhancing consumer fulfillment. Making use of a stretch wrapping machine likewise leads to a much more foreseeable budgeting process, as the amount of stretch film utilized per pallet is regular, unlike manual wrapping which can differ greatly.

Ultimately, the advancing financial savings in labor, materials, and potential product loss make the first financial investment worthwhile. In the long-term, companies can attain substantial economic benefits by integrating a stretch wrapping machine into their packaging process.

Verdict

Although effectiveness might not be the very first point you think of when thinking about stretch read this article covering devices, it is an essential aspect that can significantly affect your product packaging process. The maker's power consumption is one more critical element, as a maker that uses less energy can reduce operating expenses. In addition, a machine supported by a detailed warranty and exceptional consumer service can relieve potential problems in keeping the machine's ideal efficiency.To recognize the ways in which a stretch wrapping machine decreases waste, one have to first think about the ingenious design of these devices. In this method, stretch wrapping machines not only enhance the quality of packaging however likewise promote an extra efficient and environmentally-friendly process, demonstrating their vital duty in modern-day product packaging procedures.

Comments on “How a stretch wrapping machine reduces packaging waste”